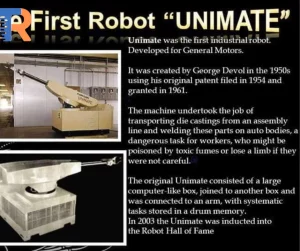

when was the First Industrial Robot. In 1962, the US saw the ascent of the world’s presentation current robot, a thought achieved by American architect George Charles Devol, Jr. in 1954.

In the annals of mechanical movement, certain accomplishments stand separated as critical events that have reshaped endeavors and social orders something very similar. One such accomplishment occurred in 1962, when the world saw the creation of the essential present day robot. Brought into the world from the visionary cerebrum of American planner George Charles Devol, Jr., this significant improvement meant the start of one more period in collecting, motorization, and the association among individuals and machines.

You Know About: Hi-Tech Robotic Systemz

The Genesis of an Idea

The groundworks of the Essential First Industrial Robot follow back to 1954, when George Devol conceptualized a machine that could perform endeavors freely, duplicating the exercises of a human arm. Devol’s vision was significantly impacted by his experiences as a maker and financial specialist, and not completely firmly established to change the gathering scene. His creative idea depended on a contraption that could be changed to do drawn-out endeavors with exactness, as such freeing human experts from ordinary and potentially hazardous commitments.

The Unveiling of Unimate First Industrial Robot

Eight years ensuing to thinking about the idea, in 1962, George Devol finally revived his brainchild. He named the machine “Unimate,” one more method for saying “General Computerization.” Unimate was a vital achievement of planning — a six-turn mechanical arm that could execute different modified tasks in a controlled and repeatable manner. Its show signified an enormous change in gathering processes, as it hailed the advancement from relying solely upon human work to solidifying robotized equipment.

Unimate’s First Steps

General Motors (GM) transformed into the primary association to embrace the ability of Unimate. First Current Robot In 1961, GM teamed up with Devol and his association, Unimation, to convey the fundamental Unimate robot on the successive development framework at the association’s pass on extending plant in New Jersey. This leading move displayed Unimate’s capacities, in actuality, as the robot performed endeavors like stacking and unloading significant metal parts into machines, really streamlining the creation cycle.

Impact and Legacy of First Industrial Robot

The introduction of the First Industrial Robot meant an extremely important occasion in various organizations. Unimate’s flourishing at General Motors impelled various producers to examine the expected results of motorization, inciting the sluggish consolidation of robots into consecutive development frameworks, handling plants, and creation workplaces all around the planet. This progress extended viability and productivity as well as additional created workplace security by reducing human receptiveness to unsafe tasks.

Also, the approaching of present day robots laid out the basis for future improvements in cutting edge mechanics and computerization. The advancement continued to create, prompting an enormous number of mechanical applications past collecting, including clinical consideration, arranged tasks, and even space examination.

Bottom Line:

The presentation of the First Industrial Robot in 1962, restored by the visionary cerebrum of George Charles Devol, Jr., signified a defining moment in humanity’s arrangement of encounters. The introduction of Unimate upset gathering processes, presenting a time of robotization that continues to shape organizations straight as of recently. Devol’s leading idea changed how things were made as well as cleared a path for a future where individuals and machines collaborate in habits that were once seen as the stuff of science fiction. The custom of the key current robot lives on in each modernized cycle, assisting us with recollecting the power of improvement to reshape the world.

What was the Purpose of the First Industrial Robot?

- The mechanical arm, weighing 4000 pounds, was responsible for moving fail miserably castings from a successive development framework and performing welds on vehicle bodies. This task was stacked with risk for human workers, as they stood up to risks, for instance, logical receptiveness to cripple gases provoking hurting or the opportunity of member wounds if not careful.

- The really current robot, named “Unimate,” was made with the fundamental job of mechanizing and streamlining gathering processes. Made by American originator George Charles Devol, Jr., the robot was expected to perform excess tasks in a cutting edge setting, subsequently decreasing the necessity for human experts to take part in dull and habitually really mentioning practices on mechanical creation frameworks and in assembling plants.

- Unimate’s colleague was a response with the creating prerequisite for extended efficiency, exactness, and prosperity in gathering. It was intended to manage tasks that important precision and consistency, for instance, lifting and moving profound articles, welding, and performing other mechanical exercises. By means of motorizing these endeavors, producers could chip away at the idea of their things, update effectiveness, and lay out a safer work area by restricting the bet of wounds related with troublesome work.

- General Motors, the essential association to embrace Unimate, involved the robot for tasks like stacking and unloading profound metal parts in their pass on projecting plant. This application sped up creation as well as allowed human workers to focus in on extra perplexing and worth added tasks that fundamental heading and decisive reasoning skills.

- By and large, the super current robot’s inspiration was to familiarize computerization with gathering processes, provoking extended capability, further grew thing quality, and the potential for human workers to participate in additional critical level tasks. This remarkable advancement laid out the basis for the broad gathering of current robots across various endeavors and ready for extra degrees of progress in robotization development.

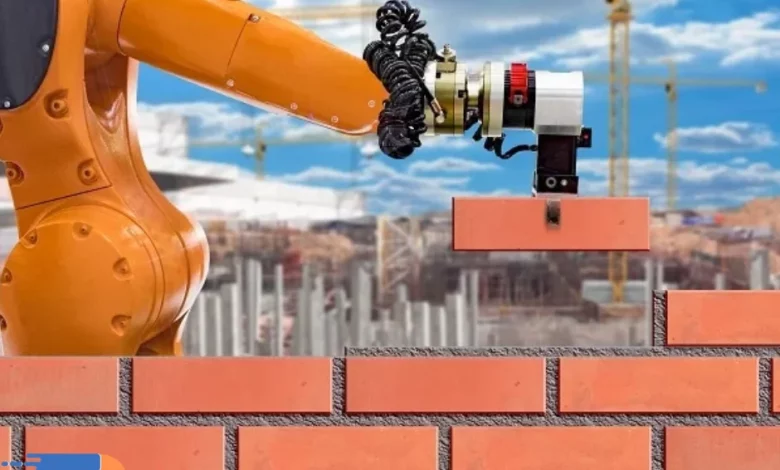

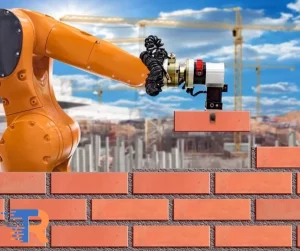

ADVANCED CONSTRUCTION ROBOTICS

Revolutionizing Construction: The Rise of Advanced Construction Robotics

The advancement business, long depicted by its work raised cycles and reliance on customary strategies, is going through an outstanding change thanks to the quick movement of mechanical innovation and motorization developments. From autonomous bricklayers to computerized exoskeletons, significant level advancement mechanical innovation are reshaping the way that designs are arranged, fabricated, and stayed aware of. This article plunges into the exhilarating area of state of the art improvement progressed mechanics, exploring their capacity to further develop efficiency, security, and practicality in the gathered environment.

The Changing Landscape of Construction

In light of everything, improvement has been a region enthusiastically subject to troublesome work, with endeavors going from bricklaying to genuinely troublesome work mentioning genuine exertion and drawn-out attempts. In any case, the ascent of state of the art improvement mechanical innovation is changing this scene by introducing imaginative plans that address a part of the business’ most pressing hardships.

- Autonomous Construction Vehicles : Free vehicles have proactively had an enormous impact in various endeavors, and improvement is no extraordinary case. Self-driving advancement gear, similar to farm trucks and excavators, can investigate complex scenes with exactness, further creating adequacy and diminishing the bet of setbacks.

- Robotic Bricklaying : Mechanical bricklaying structures are changing regular stone work. These robots are good for putting blocks with important accuracy and speed, lessening the time expected to wrap projects while staying aware of extraordinary craftsmanship.

- Drones for Site Inspection : Drones outfitted with cameras and sensors are being used for airborne outlines and site assessments. These instruments license improvement specialists to screen progress, perceive issues, and make informed decisions without the prerequisite for monotonous manual outlines.

- 3D Printing in Construction : 3D printing advancement is being harnessed to foster entire designs. Tremendous degree 3D printers can make basic parts with exactness, decreasing consume and advancement time while enabling the affirmation of confusing structure plans.

- Robotic Exoskeletons : Mechanized exoskeletons are helping improvement workers by decreasing weight on their bodies. These wearable devices offer assistance for lifting significant things, reducing the bet of wounds and further developing in everyday worker thriving.

Benefits and Challenges

The joining of state of the art improvement mechanical innovation offers an enormous number of benefits to the business:

- – Enhanced Efficiency : Robotized systems can work steadfastly, staying aware of unsurprising levels of productivity that human experts could consider to be attempting to help overextended periods.

- – Improved Safety : Hazardous and really mentioning endeavors can be assigned to robots, restricting the bet of disasters and wounds to human subject matter experts.

- – Higher Precision : Agreeing First Industrial Robot Mechanical structures can execute endeavors with unparalleled exactness, provoking better advancement results and less errors.

- – Reduced Labor Shortages : As the advancement business faces work lacks, undeniable level mechanical innovation can fill in the openings by taking on positions that are trying to staff.

Regardless, challenges persevere. The basic costs of executing computerized structures can be huge, and there may be resistance from workers stressed over work evacuation. Likewise, the specific multifaceted nature of specific structures can introduce impediments during fuse and action.

Future Outlook

The destiny of state of the art improvement mechanical innovation and First Industrial Robot is promising. As advancement continues to create, these structures will end up being more perplexing, flexible, and wise. The mix of man-made cognizance, computer based intelligence, and sensor advances will engage robots to work helpfully with human workers, updating effectiveness and prosperity.

After Have some experience with First Industrial Robot, Significant level improvement mechanical innovation are presenting one more time of headway in the advancement business. From mechanizing work concentrated tasks to introducing novel improvement strategies, these progressions are winding up significant benefits. As the business continues to embrace these degrees of progress, the created environment stands to benefit from extended viability, further created security standards, and a more practical method for managing improvement. The organized exertion between human creative mind and mechanical exactness holds the best approach to building a predominant future.

One Comment