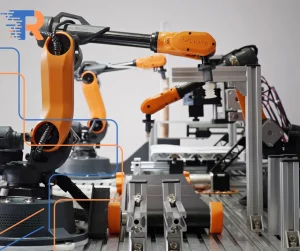

In the domain of current industry, where accuracy and effectiveness are principal, the rise of smaller than normal modern robot arms has upset the scene. These Mini Industrial Robot Arm are quickly reshaping how assembling processes are executed, rethinking working brilliant, not simply hard.

As the interest for more modest, more flexible mechanization arrangements develops, the spotlight is immovably fixed on the smaller than normal modern robot arm, a mechanical wonder that flawlessly mixes advancement, accuracy, and proficiency.

The Ascent of Smaller than normal Modern Robot Arms: A Mechanical Wonder

Gone are the days when huge, massive mechanical arms overwhelmed production line floors. The approach of little modern robot arms has opened new skylines for businesses, everything being equal, demonstrating that explosive without a doubt comes in little bundles. These reduced miracles have vanquished spatial imperatives as well as raised modern mechanization higher than ever. We offer you to study also Role of PT Industrial Robotic Automation.

A smaller than normal modern robot arm is an innovative work of art, a combination of cutting edge designing and state of the art mechanics. It flaunts many-sided plans, fastidious meticulousness, and an inborn capacity to execute errands with unrivaled accuracy. While customary robot arms frequently wrestle with space limits, smaller than expected robot arms exquisitely explore tight conditions, winding around their sorcery in perplexing cycles that once appeared to be difficult to mechanize.

Accuracy Re-imagined: The Core of Smaller than usual Modern Robot Arms

At the core of each and every smaller than normal modern robot arm lies a tenacious obligation to accuracy. These automated wonders have saddled the force of cutting edge sensors, best in class calculations, and better mechanical designing than rethink what accuracy really implies. Whether it’s collecting perplexing electronic parts or carefully dealing with delicate materials, smaller than normal robot arms show a degree of exactness that was once the domain of human craftsmanship.

The consolidation of accuracy into the DNA of smaller than usual robot arms stretches out past the actual mechanics. These machines frequently work couple with complex programming, empowering continuous changes and moment adjustments. The outcome is an amicable dance of mechanics and programming, a movement of accuracy that ensures immaculate execution as well as adjusts to the unique requests of current assembling.

The Power of Mini Industrial Robot Arms

Productivity has for some time been the north star directing modern advancement, and small modern robot arms have held onto this guideline with a bad habit like hold. These limited scale ponders have broken the thought that size is straightforwardly corresponding to capacity. Furnished with dexterity and flexibility, smaller than expected robot arms skim through many-sided fabricating processes, decreasing process durations and increasing efficiency.

What sets smaller than normal robot arms separated is their natural capacity to adjust to various assignments quickly. Through the proficient trading of end-effectors and the consistent reinventing of work processes, these machines change starting with one undertaking then onto the next without thinking twice. This versatility smoothes out creation lines as well as diminishes the requirement for personal time and reconfiguration, a demonstration of the intrinsic proficiency of these mechanical colleagues.

The Versatility Quotient: From Factory Floors to Research Laboratories

One of the most enthralling traits of small modern robot arms is their flexibility. These robots rise above the limits of conventional assembling floors, tracking down their place in a horde of businesses. From auto sequential construction systems to many-sided clinical gadget manufacture, from hardware creation to fragile logical tests in research labs, small robot arms have woven themselves into the actual texture of present day development.

In the domain of innovative work, smaller than usual modern robot arms offer researchers and designers a material of boundless potential outcomes. With their agile developments and accuracy control, these robots help in tests that request sensitive taking care of and pinpoint exactness. Whether it’s controlling natural examples, gathering small size gadgets, or leading multifaceted tests, little robot arms have arisen as essential devices, enhancing human capacities in manners that were once held for sci-fi.

Challenges and Future Trajectory: Navigating the Path Ahead

Likewise with any extraordinary innovation, the reconciliation of scaled down modern robot arms into different enterprises has not been without its difficulties. The complexities of programming, the requirement for consistent human-robot joint effort, and the affirmation of security norms are viewpoints that keep on advancing. Nonetheless, these difficulties are venturing stones, not hindrances, on the way toward a more mechanized, proficient, and imaginative future.

Looking forward, the direction of scaled down modern robot arms is certainly encouraging. As headways in man-made reasoning, AI, and sensor innovation keep on unfurling, the potential for significantly more noteworthy accuracy, proficiency, and versatility is endless. The combination of human imagination and mechanical ability vows to birth new applications and businesses, moving humankind into a time where joint effort among man and machine turns into the standard.

Conclusion: A Small Revolution with a Giant Impact

In the terrific embroidery of modern development, the smaller than expected modern robot arm remains as an image of advancement understood. Its smaller height gives a false representation of its colossal potential to reshape enterprises, rethink accuracy, and intensify productivity. From exploring multifaceted gathering errands to carrying out sensitive surgeries, these robots have demonstrated that size isn’t a limit, however a material whereupon creativity is painted.

The smaller than normal modern robot arm isn’t simply a device; it’s a demonstration of human insight and designing ability. As these little yet considerable machines keep on walking into the future, they welcome us to rethink the limits of what’s conceivable. They coax us to embrace a reality where computerization, accuracy, and productivity interlace flawlessly, cultivating a future where enterprises flourish, development thrives, and the craft of the conceivable is persistently reclassified.

How Much Does a Small Robot Arm Cost?

The expense of a smaller than usual modern robot arm can change broadly contingent upon elements like brand, determinations, capacities, and expected applications. Nonetheless, costs might have changed from that point forward, so counseling producers or wholesalers for the latest estimating information is fundamental.

- Entry-level smaller than usual modern robot arms intended for fundamental mechanization undertakings could begin at around $10,000 to $20,000. These robot arms ordinarily offer lower payload limits and essential programming capacities.

- For further developed smaller than usual modern robot arms with higher accuracy and adaptability, the value reach can stretch out from $20,000 to $50,000 or more. These robots frequently accompany better form quality, extra highlights like sensors for upgraded wellbeing and exactness, and more complex programming choices.

- If you’re searching for first in class small scale modern robot arms with state of the art innovation, cooperative abilities, and high level programming reconciliation, the expense can go from $50,000 to a few hundred thousand bucks. These superior robot arms are equipped for perplexing undertakings and consistent joining into complex assembling work processes.

- Keep at the top of the priority list that the underlying expense isn’t the main thought. Extra costs could incorporate preparation, programming licenses, end-effectors custom fitted to your particular errands, continuous support, and potential mix costs.

To get exact and exceptional estimating data for small scale modern robot arms, it’s prescribed to straightforwardly contact producers or approved merchants of the robot arm brands you’re keen on. They can give you precise insights concerning the expenses related with explicit models and arrangements that line up with your prerequisites.

Robot Arm Prosthetic vs. Mini Industrial Robot Arm:

In the realm of advanced mechanics and innovation, two particular yet similarly historic headways certainly stand out: the robot arm prosthetic and the scaled down modern robot arm. These developments, albeit created for immeasurably various purposes, share an ongoing idea of upgrading human potential and computerization productivity. We should dive into the extraordinary characteristics of each and investigate how they are molding the scene of advancement.

Robot Arm Prosthetic: Restoring and Empowering Lives |

Mini Industrial Robot Arm: Precision and Efficiency in Manufacturing |

| The robot arm prosthetic stands as an encouraging sign for people who have encountered appendage misfortune. It addresses an intermingling of state of the art designing, neuroscience, and human-focused plan.

The essential objective of a robot arm prosthetic is to reestablish actual usefulness as well as close to home prosperity and freedom for its clients. |

On the opposite finish of the range lies the smaller than usual modern robot arm, a force to be reckoned with of accuracy and proficiency in the realm of assembling and computerization.

Not at all like its bigger partners, the little modern robot arm is minimal yet powerful, intended to explore restricted spaces and execute unpredictable assignments with careful exactness. |

| At its center, a robot arm prosthetic is a wonder of biomechanical designing. Through the mix of sensors, actuators, and high level calculations, it makes an interpretation of the client’s goals into exact developments, copying the normal usefulness of a human appendage.

For tragically handicapped people, this implies recovering the capacity to perform day to day undertakings that were once underestimated, like getting a handle on objects, composing on a console, or holding a friend or family member’s hand. |

The scaled down modern robot arm is a demonstration of the combination of mechanics, gadgets, and man-made reasoning. Outfitted with sensors, engines, and shrewd programming, it can play out a large number of errands that once required human mediation.

From gathering many-sided parts in hardware creation to leading exact quality checks in auto producing, these robots have re-imagined the scene of modern cycles. |

| The effect of a robot arm prosthetic stretches out past its mechanical capacities. It sustains a feeling of strengthening, ingraining certainty and empowering people to reconnect with life in their own specific manner.

Whether it’s seeking after a vocation, getting a charge out of side interests, or cooperating socially, the prosthetic turns into an expansion of the singular’s character, epitomizing strength and the victory of human soul. |

What sets small scale modern robot arms separated is their flexibility. They can be effectively reconstructed and reconfigured to deal with various assignments, decreasing free time and improving creation productivity.

Their little size permits them to be coordinated into smaller creation lines, streamlining space and assets. Basically, they embody how innovation can improve modern efficiency without forfeiting accuracy. |

Bridging the Gap: Common Threads and Shared Goals

While robot arm prosthetics and little modern robot arms might appear completely different, they share ongoing ideas that highlight the capability of human-robot cooperation. The two advancements highlight the extraordinary force of innovation to improve lives and smooth out processes.

The two advancements feature the meaning of customization. Robot arm prosthetics are customized to fit the remarkable necessities and inclinations of individual clients, while small modern robot arms can be modified to suit explicit assembling prerequisites. This emphasis on personalization highlights the shift towards innovation filling in as an expansion of human capacities, whether it’s in a medical care or modern setting.

Besides, the two advancements encapsulate the standards of accuracy and effectiveness. Robot arm prosthetics expect to repeat regular developments with precision, while little modern robot arms execute mind boggling errands with careful scrupulousness. This quest for flawlessness addresses the capability of joining human inventiveness with mechanical progressions to accomplish results that were once considered impossible.

Conclusion: A Shared Vision for Progress

In a quickly developing mechanical scene, the robot arm prosthetic and the small modern robot arm stand as images of progress and probability. They embody the intrinsic cooperative energy between human potential and mechanization proficiency. As we keep on pushing the limits of advancement, these two domains help us that the combination to remember innovation and humankind has the ability to reshape lives, ventures, and the world overall.

FAQs

When was the mini industrial robot arm invented?

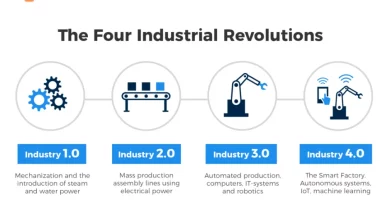

The concept of industrial robot arms dates back to the mid-20th century, with the introduction of the first industrial robot by George Devol and Joseph Engelberger in 1954. However, the development of mini industrial robot arms, specifically designed for compact spaces and intricate tasks, gained prominence in the late 20th and early 21st centuries. The exact date of the invention of the first mini industrial robot arm can vary based on specific models and manufacturers.

What is a mini industrial robot arm?

A mini industrial robot arm is a compact and versatile robotic device designed for performing a wide range of tasks in industrial settings. These robots are characterized by their smaller size, which allows them to navigate tight spaces and execute precise tasks with high accuracy. Mini industrial robot arms are often used in manufacturing, electronics assembly, research laboratories, and other environments where space efficiency and precision are essential.

What are the advantages of mini industrial robot arms?

Mini industrial robot arms offer several advantages, including: - Space efficiency: Their compact size allows them to fit into tight spaces. - Precision: They can perform intricate tasks with high accuracy. - Versatility: They can be reprogrammed for various applications. - Cost-effectiveness: They can be a more affordable automation solution compared to larger robots. - Adaptability: They can be integrated into existing production lines with minimal disruption.

What industries use mini industrial robot arms?

Mini industrial robot arms find applications in various industries, including: - Electronics manufacturing - Automotive assembly - Pharmaceuticals - Food and beverage production - Research and development laboratories - Medical device fabrication - Small-scale production and prototyping

How do mini industrial robot arms work?

Mini industrial robot arms consist of robotic manipulators with multiple joints and links, controlled by motors and actuators. They often include sensors for feedback and precise positioning. Programming and control software allow users to define tasks and movements. Some mini robot arms can be programmed using teach pendant interfaces, while others can be integrated with automation systems and controlled via software interfaces.

Can mini industrial robot arms collaborate with humans?

Yes, many mini industrial robot arms are designed for collaborative applications. These robots are equipped with safety features, such as force sensors and collision detection, that allow them to work safely alongside human operators. Collaborative mini robot arms are used in tasks where human-robot teamwork is essential, such as small-scale assembly and delicate procedures.

What is the cost of a mini industrial robot arm?

The cost of a mini industrial robot arm can vary based on brand, specifications, capabilities, and customization. Entry-level models might start at a few thousand dollars, while more advanced and feature-rich models can range from tens of thousands to over a hundred thousand dollars.

Are mini industrial robot arms easy to program?

Many manufacturers provide user-friendly programming interfaces for mini industrial robot arms. Some offer graphical interfaces that allow users to visually program tasks, while others use coding languages. Additionally, advancements in software have made programming and reprogramming robot arms more intuitive and accessible.

Can mini industrial robot arms be integrated into existing systems?

Yes, mini industrial robot arms are designed for easy integration into existing production lines and automation systems. They can be equipped with interfaces for communication with other machines, sensors, and control systems.

What is the future of mini industrial robot arms?

The future of mini industrial robot arms holds promise for continued advancements in precision, adaptability, and ease of use. As technologies like artificial intelligence, machine learning, and sensor technology evolve, mini robot arms are likely to become even more intelligent, capable of handling a wider range of tasks, and seamlessly collaborating with human operators.

One Comment