The oil and gas industry, the foundation of the world’s energy supply, winds up at the beginning of an innovation that vows to reclassify its working environment. Advanced mechanics in the oil and gas industry, driven by propels in knowledge, robotization and identification innovation, is arising as a focal power in reshaping how the business investigates, removes and deals with its assets. In this article, we dig profound into the intricacies among advanced Robotics in oil and gas industry, uncovering how these developments are adding to somewhere safe and secure, security and maintainability.

Working proficiently and precisely in exploration and swimming

Present day robots in the oil and gas industry are opening new wildernesses in investigation and penetrating, changing customary cycles and introducing another period of development and proficiency. Submerged vehicles (AUVs) and mechanically worked vehicles (ROVs) presently explore the profundities, directing submerged reviews and gathering information without uncovering people. unique and risky circumstances. The automated penetrating framework streamlines the well framework with unimaginable precision, empowering ongoing information examination for better independent direction. For industerial work we research the more special 3D Machine Vision For Industrial Robots.

Enhance efficiency with mechanization

Robotization is an empowering agent of effectiveness in the creation cycle. Mechanical interaction mechanization (RPA) has entered administration jobs, liberating human specialists to zero in on essential preparation. Independent creation frameworks exhibit their capacities by working from a distance without issues, lessening the requirement for on location laborers and keeping up with efficiency. Advanced mechanics in the oil and gas industry Robots, furnished with current cameras and sensors, act top to bottom examinations, guarantee the uprightness of gear and expect likely harm.

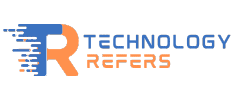

Security Restored: Advanced mechanics Assessment and Upkeep in the Oil and Gas Industry

The dangers innate in oil and gas establishments require cautious checking and support, a region where advanced mechanics sparkles with unrivaled potential. Advanced mechanics in the oil and gas industry, crawlers and climbers move around complex designs and pipelines, precisely assess and identify abandons, hence decreasing apprehension about man. Airborne robots, furnished with warm cameras, enter distant regions, recognizing expected wrongdoings or glitches in offices that sounds stowed away. Prescient upkeep, empowered by advanced mechanics and sensors, diminishes surprising personal time, and advances quicker control.

Driving Assistance from new Robotics in Oil and Gas Industry

In a time of growing regular care, mechanical innovation in the oil and gas industry is prepared to help sensibility in the oil and gas industry. Drones with one of a kind sensors perceive and recognize gas surges, thusly avoiding likely natural disasters. The modified structure upgrades energy usage, helping with diminishing outpourings and carbon impression. As cutting edge mechanics and efficient practices get together, the environmental impact of the business is all set through huge changes. Making skilled workers

As robots in the oil and gas industry augmentation and play out unambiguous endeavors. It is all the while progressing new areas of master fitness. Staying aware of, programming and supervising mechanized structures requires capable workers, describing standard tasks and vivifying the exchanging of capacities inside the association. This helpful association among man and machine plans for updated capacities and specialization, preparing for serious solid areas for a solid workforce.

End: embrace the high level mechanics uprising

As the oil and gas industry pushes ahead into a future described by improvement, mechanical innovation in the oil and gas industry is emerging as a fearsome player in this change story. From assessment to creation, security and support, the collaboration between human understanding and extraordinary advancement allows the association to enter obscure spaces. As robots perfectly integrate into the surface of work, they become contraptions, yet moreover accessories, further creating efficiency, defending lives and dealing with quality. additionally, very tough. The marriage of mechanical innovation in oil and gas gives a shocking vision addressing things to drop by getting human information together with creative progression.

What are five motivations behind robots in industry and society?

Robots have found various applications across industry and society, giving game plans that further foster capability, security and quality. Coming up next are five critical reasons for robots::

Assembling and Industry:

- – Computerized get together: Robots are utilized for dull and exact undertakings in assembling, like part gathering, welding and quality control. They further develop efficiency and solidness and decrease human mistake. – Material dealing with: modern robots lift, endlessly transport weighty items in plants and distribution centers, accelerating fixes and decreasing the gamble of specialist wounds.

- – Bundling and palletizing: robots pack items, orchestrate them on beds and set them up for shipment, in this manner enhancing the bundling system and working on the effectiveness of the production network. – Quality assessment: Robots with vision review items for surrenders, guaranteeing reliable quality and diminishing the opportunity of inadequate items arriving at customers.

- – 3D printing: mechanical arms can be utilized in added substance producing processes, making strong models and designs. Wellbeing and medication:

- – Careful help: Automated a medical procedure frameworks assist specialists with carrying out complex methodology all the more proficiently, with less disturbance and quicker recuperation times.

- – Recovery: Robots aid non-intrusive treatment for patients recuperating from injury or medical procedure, giving controlled practice and further developing restoration results. – Telemedicine: Robots outfitted with cameras and sensors permit observing among specialists and patients, particularly in regions with restricted clinical access.

- – Medication assortment: In medical clinics and facilities, robots control medication accurately, diminishing medicine mistakes and opening up clinical staff time to zero in on persistent consideration. – Assistive gadgets: Robots planned as exoskeletons or portability helps increment the versatility and autonomy of individuals with restricted portability.

Horticulture:

- – Proficient cultivating:

Robot ranchers, furnished with sensors and GPS, screen the soundness of harvests, apply pesticides and plant crops, accordingly expanding the endlessly yield. – Gathering: Robots are utilized for programmed collecting of harvests, for example, leafy foods, in this way decreasing work costs and further developing effectiveness.

- – Weed and vermin control:

Robots with cameras and computer based intelligence recognize and kill weeds, diminishing the requirement for herbicides. They can likewise target bugs that don’t influence gainful bugs.

- – Drones in agribusiness:

Robots (drones) screen and guide huge rural fields, giving important information about crop well being, dampness levels and expected issues. Obligations and Acknowledgment:

- – Client care:

Robots are introduced in lodgings, air terminals and retail locations to help clients, answer questions and guide visitors to their objective..

- – Food administration:

cafés and lodgings use robots for food planning, cooking and serving, further developing velocity and effectiveness and keeping up with sanitation.

- – Cleaning and support:

Robots clean themselves and keep up with the climate, for example, floors and windows in business spaces, decreasing work costs and guaranteeing steady neatness.

- – Amusement:

Robots are utilized in amusement parks, historical centers and diversion scenes to communicate with guests, giving an enlightening and drawing in experience.

- – Security:

Robots outfitted with cameras and sensors safeguard and screen the region, further developing security and checking capacities. Instruction and Exploration:

- – STEM Instruction:

Robots are utilized as helping apparatuses to show understudies science, innovation, designing and arithmetic through exercises and trials.

- – Research partners:

Robots assist specialists with gathering information, perform tries, and perform redundant assignments, along these lines accelerating logical examination.

- – Space investigation:

Robots, for example, wanderers and landers are put on different planets to investigate and gather information in conditions where human presence is unthinkable.

- – Archeological investigation:

Submerged robots investigate wrecks and submerged archeological locales, safeguarding social legacy and revealing verifiable data.

- – Ecological checking:

Robots gather information on air, water quality and untamed life conduct, adding to natural examination and preservation endeavors.

These different applications exhibit the progressive capability of robots to further develop effectiveness, security and personal satisfaction in industry and society overall.

What are 3 industries that use robots?

Robots are utilized in different enterprises to further develop effectiveness, efficiency and well being. The following are three significant ventures that utilization robots widely:

Make:

- The assembling organization is one of the trailblazers in mechanical innovation.

- Robots are utilized for various assignments in industry, including gathering, welding, painting, material dealing with and quality control.

- Modern robots succeed at performing dull and exact errands, prompting further developed efficiency, steady quality, and diminished human blunder.

- With the appearance of cooperative robots (cobots), human-robot coordinated effort has become typical, permitting robots to work with human laborers to expand their productivity.

Drive:

- The auto business depends vigorously on advanced mechanics in the oil and gas industry to further develop creation processes and guarantee great vehicles.

- Robots are utilized in errands, for example, body welding, part gathering, painting and quality control.

- Robotization in the auto area has prompted expanded efficiency, productivity and well being for laborers.

- Robots with cutting edge sensors and imaginative frameworks can perform complex undertakings with accuracy, adding to the creation of dependable and mechanically progressed vehicles.

Coordinated factors and Warehousing:

- The coordinated factors and warehousing industry has seen the rising utilization of robots to further develop store network tasks.

- Robots, like mechanized directed vehicles (AGVs) and independent portable robots (AMRs), travel through stockrooms to ship merchandise, sort bundles and coordinate products.

- The robots utilized in the oil and gas industry are more proficient in dealing with dull materials, accordingly lessening work costs and further developing stock administration.

- Also, drones are utilized for stock following, following, and last-mile conveyance in the coordinated operations industry.

- These organizations make different robots to work on functional productivity, decrease work concentrated assignments, and advance innovative advancement.

- As mechanical technology innovation in the oil and gas industry keeps on creating, different enterprises might embrace robots to acquire an upper hand and adjust to the present evolving scene.

FAQs

How are robots used in the manufacturing industry?

Robotics in oil and gas industry are used in manufacturing for tasks like assembly, welding, painting, and quality inspection. They automate repetitive processes, ensuring precision and consistency. Collaborative robots (cobots) and Robotics in oil and gas industry also work alongside human operators, enhancing efficiency and safety in factories.

What role do robots play in the automotive industry?

In the automotive sector of Robotics in oil and gas industry, robots are integral to tasks such as welding car bodies, assembling components, painting, and quality control. They accelerate production, improve accuracy, and ensure the creation of high-quality vehicles, contributing to the advancement of automotive technology.

How do robots optimize logistics and warehousing operations?

Robots, including AGVs and AMRs, navigate warehouses to transport goods, sort packages, and manage inventory. These robots and Robotics in oil and gas industry improve efficiency by handling repetitive material handling tasks, reducing errors, and enhancing inventory management processes.

What types of tasks can robots perform Robotics in oil and gas industry?

Robotics in oil and gas industry in manufacturing excel at tasks like welding, painting, and assembly. In the automotive sector, they contribute to car body welding, assembly line tasks, and precision quality checks. In logistics and warehousing, robots handle material transport, sorting, and inventory organization.

How do robots contribute to workplace safety in these industries?

Robots enhance workplace safety by handling hazardous or repetitive tasks that pose risks to human workers in Robotics in oil and gas industry. They reduce human exposure to dangerous conditions, ensuring a safer working environment. Additionally, collaborative robots are designed to work safely alongside humans, enhancing overall operational safety.

One Comment