In the ever-changing arena of industrial automation, exactness, speed, and loyalty are critical. To address these requirements, businesses are progressively turning to advanced technologies such as 3D vision systems. Among these developments, the Zivid 2 bin picking Cameras are gaining fame for their matchless abilities in industrial 3D imaging. In this article, we’ll look at how the Zivid 2 3D camera is redesigning industries by present exact and reliable 3D point cloud data, transforming applications like robotic automation, bin-picking, and quality control.

The Time of 3D Vision Taken with Zivid

3D vision technology has altered industrial automation by permitting machines to view and understand their surrounds in three magnitudes while on-arm.

This technology is founded on collecting 3D point-cloud data, which shows the 3-D organizes of items in a scene. This data is serious for applications like item finding, location, following, and quality valuation. 100ms

The Zivid 2 3D Fact Camera Robot

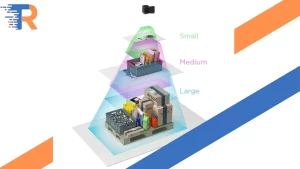

The Zivid 2 3D camera is at the radical of this technological revolt. It stands-out for its great act, ease of incorporation, and adaptability across an inclusive array of industrial applications. Zivid 2 is presented in two forms: Zivid 2 Plus and Zivid 2 M70, each personalized to individual needs.

Key Structures of Zivid Two Idea Cloud:

- High-Quality 3D Point-Clouds:

The Zivid Two camera gathers 3D point-cloud data with notable exactness and accuracy, making it ideal for the most challenging industrial applications. It can influence a working distance of up to 1,000 mm, allowing a sharp and comprehensive vision of objects even in difficult conditions.

- Fast and Accurate:

Zivid Two has excellent speed, taking 3D point clouds in 100 milliseconds with a solo capture. Fast data assembly is serious for real-time applications, as speed can significantly affect output and competence.

- Extensive Field of View:

The camera’s inclusive field of view allows it to “see everything” in its mark of sight. This wide-ranging viewpoint is particularly valuable for applications like bin picking and robot automation, where a thorough hold of the settings is essential.

- Single Combination of Machine Vision Algorithms:

Zivid Two uses progressive machine-vision algorithms to enhance 3D-point cloud data for correctness and dependability. These algorithms include division, sorting, and standardization, which play an important part in assuring the highest quality results.

Applications of Zivid Two 3D Camera Arena of Sight

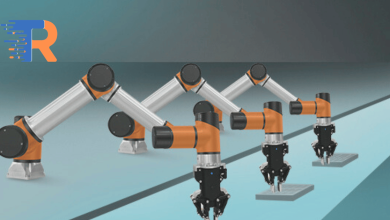

- Robotic Automation:

The Zivid Two industrial robot is a game modifier. Its particular 3D camera point-cloud data allows robots to discover, operate, and relate with items in an accurate manner. The camera’s correctness and reliability confirm that automation jobs are completed successfully, whether they contain delicate electronic apparatuses or huge machinery parts. This principals to higher manufacture, rarer mistakes, and cost reserves.

- Bin Picking:

Bin picking, in which robots autonomously select objects from a bin, has usually been a problematic process due to the variety of object site and location. Zivid Two’s quick and exact 3D imaging, along with its machine visualization procedures, makes bin selecting informal. The camera can recognize and find things in an overfilled environment, letting for well-organized section selection in logistics and creation.

- Quality Control:

Certifying the superiority of industrial objects is serious in many sectors. Zivid Two excels in value control applications because it offers a complete 3D standpoint of mechanisms and goods. Its volume to yield true-to-life images allows correct dimensions, flaw finding, and external examination. This level of exactness is critical for preserving product value and stopping faults from incoming the market.

- Correction and Synchronization:

Zivid Two contains correction and synchronization structures, which rise its worth in robot applications. It can be put on a robot and adjusted to work with other mechanization devices. This confirms that the camera’s 3D point cloud data agrees faultlessly with the robot’s actions, thus increasing general system correctness.

Read More: NASA Snake-like Robot

Zivid 3d: The Next Edge Bin-Picking Working Capacity

Zivid’s assurance to invention produces alongside technological advancements. The Zivid Three 3D camera is the most current addition to the Zivid family, present even more structures and improvements. Zivid Three increases the bar for industrial 3D vision with advanced picture quality, a longer working distance, and improved machine vision procedures.

Zivid Three’s high act and usefulness make it faultless for industrial settings where accuracy, speed, and reliability are critical. Its influential 3D imaging abilities will additionally enhance robot automation, bin-picking, value control, and a variety of applications across industries.

Advantages of a 2D Combined and view in 3D System

Several businesses are joining 2D and 3D vision technologies to offer a more complete view of their functioning environment. While 3D visualization is best at profundity insight and object localization, 2D vision offers valuable data about object surface, color, and designs. The mixing of both technologies, known as a “unified 2D and 3D vision system,” improves machine awareness and supervisory.

Zivid knows the implication of this interaction and has created resolutions that relate easily with industrial 2D cameras. This sole mixture allows businesses to influence the skills of both technologies, making their automation and quality control systems even more vigorous and effectual.

3D Technology

In the stage of Industry 4.0, there is a more need than ever for exact and steady 3D vision systems. The Zivid Two 3D camera, and its approaching successor, the Zivid Three, are at the frontline of this technological shift. With their unequalled speed, exactness, and flexibility, these cameras help industries to reach new levels of manufacture, efficacy, and quality.

Zivid’s industrial 3D cameras are established to be vibrant tools for robot automation, bin-picking, and excellence control. Their volume to gather true-to-life 3D point cloud data is making new chances and changing how companies’ function. 3D vision Taken with Zivid, as we continue to drive the limits of what is possible in industrial automation, Zivid cameras are at the lead, confirming that businesses keep on modest and thrive in the ever-changing world of industrial and logistics.

The world of industrial automation is altering intensely, and the Zivid Two 3D+2D camera is at the center of this uprising. In a period where exactness, speed, and reliability are dangerous, Zivid Two stands out as the unequalled solution, providing a sole mix of 3D and 2D vision skills. This study explores how Zivid Two is altering industrial applications such as robot automation, pick and place procedures, and value control, while bringing matchless point cloud quality and true-to-life pictures of things.

Zivid Two: A 3D+2D Vision Center

Zivid Two is more than merely a 3D camera; it is an influential 3D+2D camera made to meet an inclusive range of industrial necessities. It faultlessly associations the benefits of both 3D Vision Taken with Zivid and 2D vision technology to deliver a complete view of objects and scenes. Let’s look at the wonderful features that make Zivid Two the finest 3D+2D camera.

- Matchless Point Cloud Quality:

The Zivid 2 bin picking Cameras technology is famous for its skill to capture clean, elegant point clouds with incomparable exactness. This high-resolution industrial 2D camera works with 3D technology to confirm that every feature is suitably captured. The end result is pointing cloud examples of hard and high lively series scenes that are second to none.

- True-to-Reality Images:

One of Zivid Two’s unique structures is its aptitude to crop realistic pictures of object size, total location, and surface normal. This correctness is vital in applications that need exactness acquisitive and operation, making it suitable for pick-and-place robots and object gratitude.

- Brilliant Accuracy and Reliability:

Pick and place procedures need exact and true imaging, which cannot be tense. Zivid Two replies to the challenge, sending highly detailed and reliable act across the whole operative temperature range. Uniformity is critical for keeping output and quality in challenging industrial settings.

Applications of Zivid Two 3D+2D Camera

- Robotic Automation:

The Zivid 2 bin picking solution surpasses at providing accurate point clouds and pictures, making it a perfect mate for robotic automation. Its aptitude to capture objects in a unified pixel-wise way confirms that robot’s role slickly and exactly. Whether it’s voidance bins, handling hard parts, or steering glossy packaging, Zivid Two reliably sends outstanding act.

- Pick and Place Procedures:

Zivid Two is the best answer for pick and place robots that need to properly hold and be able to objects of wide-ranging sizes and shapes. Its matchless point cloud quality and 3D+2D abilities enable robots to spot, classify, and pick things with high exactness. This not only hurries the process, but also reductions mistake and improves quantity.

- Quality Control:

Confirming product quality during invention is serious. Zivid Two’s 3D+2D vision abilities are very valuable for reviewing an extensive diversity of items and settings. The camera’s high-resolution photography and true-to-reality pictures are vital for behind product worth ethics, from defect exposure to dimension size.

1. What makes Zivid Two a distinctive industrial automation solution??

The Zivid 2 bin picking solution’s exclusive mixture of 3D and 2D visualization technologies produces the best value point cloud data and true-to-life pictures of things. This makes it outstanding for a change of industrial applications, as well as robot automation, pick-and-place processes, and value control.

2. How does Zivid Two confirm exactness in pick and place robotics?

Zivid 2 bin picking Cameras brilliant exactness and reliability, matching with its matchless point cloud quality, permit for exact object acknowledgment and operation. Whether supervision hard items or exchanging glossy packing, Zivid 2+ M130 bin picking cameras reliably give great act.

3. What function does Zivid Two perform in quality control??

Zivid Two’s 3D+2D vision abilities are valuable for value control jobs. It allows the detection of faults, measurement of dimensions, and examination of a variety of objects and situations using true-to-life images, confirming product quality ethics are pleased.

4. Can Zivid Two work in tough industrial environments??

Yes, Zivid 2 bin picking Cameras is planned to work consistently in severe industrial environments. It offers strong act across the entire operating temperature range, assuring reliable results even in rough settings.

Conclusion of Zivid 2 bin picking Cameras

In the fast-changing world of industrial automation, the Zivid 3D 2D camera is a game changer. Its unequalled point cloud quality, true-to-life pictures, and unified addition of 3D and 2D vision technologies make it the perfect choice for a change of applications. From robot automation to pick and place processes and value control, Zivid 2 bin picking Cameras offers exact and correct imaging, growing output and confirming the uppermost value necessities are met. As businesses continue to demand exactness, speed, and dependability, zivid’s 2 bin picking solution sets a new standard for what can be completed with 3D+2D vision technology.

I’d like to find out more? I’d love to find out some additional information.